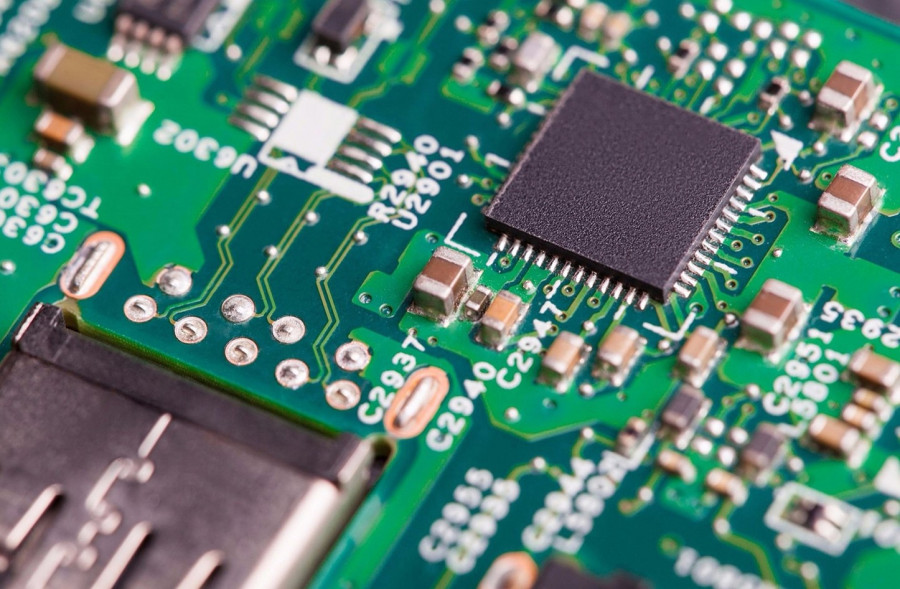

The difficulties in supporting semiconductors have been supported by semiconductors for months with a crisis for car manufacturers and giant technology companies, where these chips are taken and stored in electronic devices.

According to Arab Net, many car manufacturers in the world, including Ford and General Motors, close some of their plants and reduce their production as a result of the electronic chip supply crisis.

These ingredients intervene in the manufacture of many devices we use daily, such as smart phones, computers, video games and automotive players.

But what are the reasons behind the electronic chip crisis and why more can be manufactured to meet demand?

The industry requires huge investments for billions of dollars, and it takes the construction of several years of semiconductor facilities.

Intel, Samsung and TSMC are one of the largest electronic chips, with the most advanced factories in this area at a cost of more than $ 20 billion to build one plant.

Electronic chip manufacturers faced a sudden increase in demand for electronic products middle demand high demand on computers and electronic gaming players under the Corona crisis and what is passed from remote work and home stone.

However, the semiconductor market was mainly under pressure by the commercial war between the United States and China.

The latter worked on more independence in this area by establishing a box of about thirty billion dollars to support the semiconductor industry.

China is the largest importer and consumer of the world's semiconductor. However, they only produce 16% of semiconductor chips, pushing them to plan for 70% of its semiconductor needs by 2025.